-

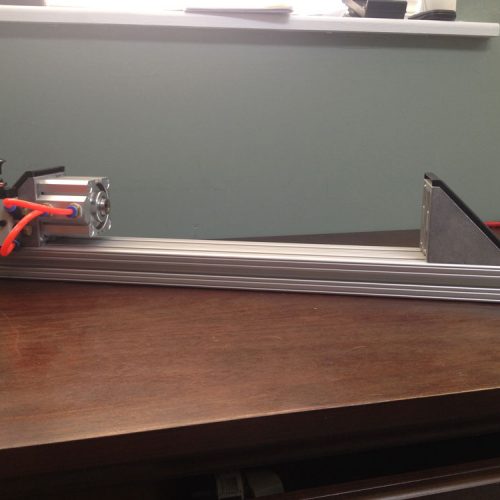

Much faster than using clamps whether it's a single mold or several molds together our adjustable Quick Clamp provides consistent pressure at a pull of the switch. If you have long molds you can use them in tandem. Custom extensions are available for molds 3 inches and over. Needs a compressor to work (not supplied).

Much faster than using clamps whether it's a single mold or several molds together our adjustable Quick Clamp provides consistent pressure at a pull of the switch. If you have long molds you can use them in tandem. Custom extensions are available for molds 3 inches and over. Needs a compressor to work (not supplied). -

Out of stock

These systems are CUSTOM BUILT and are currently on backorder.

Please fill out the form at the bottom of the page to be added to our backorder waitlist.

Telephone: 1-318-255-7144

The pots and manifold are solid aluminum, for maximum heat transfer. All parts are CNC machined in-house. Features: Ports on each pot for single color use Center manifold/port for two-color injection/lamination Pocket in the manifold for heating injector Pot lids have a view-port and hold the stirrer motor in position Stirrer motors are VARIABLE speed with a maximum speed of 75 rpm Both pots have a ceramic insulating blanket with a protective aluminum wrap The system is mounted to an aluminum base plate, with "U" brackets at each port for locking injectors in position while drawing plastic A control box is mounted under the base plate: there is a single rear power cord. Temperature controllers, motor speed controllers, and switches are mounted in the front panel, stirrer motors plug into the side panels. A ventilation fan and louvers in the side panels maintain an airflow across the controls and relays Specification: 115 VAC 20 AMPS 2 x 1000 watt heaters (8.7 amps each) Motors/Controls (0.5 amps each) Pot capacity 2 x 96 fluid ozs. (6 quarts total) 1:1 Twin Injector included 8 oz (2 x 4 oz barrels) Temperature controllers are digital, with Fahrenheit readout and temperature sensors. Temperature is maintained to within +/- 4 deg, although this can be adjusted through the controller NOTE: The cost of shipping with full insurance via UPS will be charged at a discounted rate. Due to the custom nature of these machines, please allow two to three weeks from the time of order to shipping. -

Out of stock

These systems are CUSTOM BUILT and are currently on backorder. Please contact Ultra Molds LLC to be added to our backorder waitlist.

Telephone: 1-318-255-7144

Ports and manifold are solid aluminum, for maximum heat transfer, ALL parts are CNC machined in house Center Manifold/Port for two-color injection Pocket in the manifold for heating injectors Ports for single color injection on both pots Pot lids have a viewport and hold the stirrer motors in a position Stirrer motors are VARIABLE speed with a maximum of 75 rpm Pots have a ceramic blanket for insulation and a protective aluminum wrap The system is mounted to an aluminum base plate, with U brackets at each port for locking the injectors in place while drawing plastic A control box is mounted under the base plate; there is a single rear power cord. Temperature controllers, motor speed controls, and switches are mounted in the front panel, stirrer motors plug into the side panels. A ventilation fan and louvers in the side panel cool the controls and relays Specs 115 VAC 2 x 20 amps circuits 2 x 2000 watt heaters (17.4 amps each) Motors/controllers 0.5 amps Pot capacity 8 quarts or 256 oz PER POT Temperature controllers are digital with a Fahrenheit readout and a sensor. Temperature is maintained to +/- 4 deg 1:1 Twin Injector 8 oz (2 x 4 oz barrels) 1 Pair of Hot Mill Gloves NOTE: Due to the custom nature of these machines please allow 28 working days from the time order to shipping